Monofilament yarns are usually produced in the same way as fibrillated yarns. They are manufactured by melting polymers. This process produces polymeric strands, which are then wound onto spools. This can be done either by slicing the Mother Yarn or by directly spinning the filament.

Some monofilament yarns can be produced from recycled materials. Some yarns can be textured, which reduces lustre, slipperiness, transparency, and crimp. Other monofilament yarns are hollow, which are used in softer sewing thread applications.

Nylon monofilament yarns are commonly used in the fashion industry. They are also used in sports applications, such as in badminton strings, swimming pool liners, and floatation mallard decoys. They are highly abrasion resistant, have excellent wear-resisting properties, and can be formed into a variety of shapes. They are thin, transparent, and have good water-cutting performance.

The monofilament process is similar to the production of fibrillated yarns, but the tools used are different. In addition, there are new production processes that are emerging as times require. These processes may include heat setting, or thermal-bonding, which eliminates the need for chemical bonding. The process reduces energy consumption and environmental pollution.

These processes are mainly performed in China. The majority of the monofilament yarn enterprises in China are located in the Jiangsu province. A small number of these enterprises are scattered in other regions of the country. A few of the major gathering places of two-step monofilament yarn are found in the Wuxi and Hai'an areas of Jiangsu.

For some of the larger diameter monofilament yarns, a water quenching process is used. This process produces monofilaments with diameters up to 60D. It is possible to produce smaller diameter monofilament fibers by quenching the fibers in air chambers.

Some monofilament yarns are processed by direct spinning, braiding, or weaving. These are the methods used for producing yarns for use in clothing, upholstery, and other textiles. The final product is a single strand of woven or knitted fabric, usually circular in shape. These can be a variety of shapes, including sheath/core, flat, triangular, or V-shaped. They can also be crimped, crinkled, or twisted. A professional manufacturer of monofilament yarns will adjust the formula depending on the type of yarns being produced.

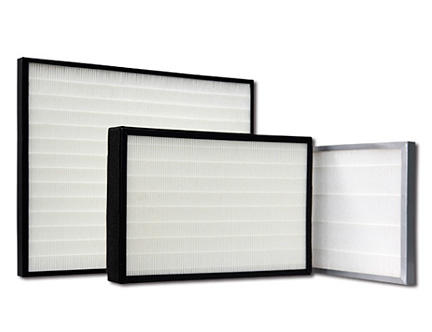

In addition to its use for weaving and sewing, polymer monofilament fabrics are also used for filtration, architectural decoration, and in filtering equipment. Other uses of these fabrics include elastomeric pressure garments. They limit hypertrophy and contraction of scar tissue. These products are often made from high molecular weight polypropylene, which has a low melting point and is easy to extrude.